Services that we provide:

- Custom Metal Fabrication

- Laser/Plasma Cut Parts

- Powder Coating

- Part Sizes up to 3′ X 6’X 11′

- Traveling Installation Crews

Our crews have decades of experience working in peanut processing plants, sawmills, food production facilities, furniture plants, etc.

Some of the various types of systems that our crews have installed are Dust Collection Systems using Cyclones and Baghouses, Various Types of Mechanical Conveyors, High-Pressure Pneumatic Conveyors, Screw Aggers, Ventilation Hoods, etc.

DUST COLLECTION

Baxley Companies specializes in the Design, Fabrication, and Installation of High-Efficiency Dust Collection Systems for a wide range of industrial applications. Our Systems can be found in many Peanut Processing Facilities and Sawmills throughout the United States.

Our Proprietary High-Efficiency Cyclones carry a 99.5% Efficiency Rating down to a particle size of 5 Microns. These Systems Come complete with a Support Superstructure, Access Platforms (Designed around Customers’ Specific Needs), and an appropriately sized Centrifugal Fan.

For Systems Requiring a more Efficient Collector, we can include an appropriately sized Baghouse by working with our Industry Partners.

Relying on our years of experience in the industry, we can recommend the best system to suit your filtration needs.

INDUSTRIAL VENTILATION

Our expertise also encompasses Building Ventilation and Fume Collection. Through the use of specially designed hoods, we can capture, move, and expel heat and toxic fumes from worker areas in a clean and efficient manner.

Our Ventilation systems have been installed across the entire Continental United States for customers, including the leading bottled water manufacturer in the US, as well as other Fortune 500 companies.

Working with Equipment Manufacturers, we can match materials and paint/powder coat colors to ensure a seamless installation that looks like a factory-installed option.

SYSTEM DESIGN & INSTALLATION

At Baxley Companies, we pride ourselves on our principle of CONCEPT TO REALITY. Utilizing our industry-leading design software, we can interpret your ideas and sketches into working drawings and even a full 3D Render.

From there, we can generate fabrication and installation drawings using that model. By utilizing these tools, our Installation Crews and in-house fabricators are on the same page about what they are building.

We implemented the 3D Modeling Software in 2021, and since then, we have seen a decrease in the amount of construction waste on job sites and in the amount of time spent troubleshooting problems encountered during the build.

HIGH PRESSURE SYSTEMS

Baxley Companies specializes in the Design, Fabrication, and Installation of High-Efficiency Dust Collection Systems for a wide range of industrial applications. Our Systems can be found in many Peanut Processing Facilities and Sawmills throughout the United States.

Our Proprietary High-Efficiency Cyclones Carry a 99.5% Efficiency Rating down to a particle size of 5 Microns. These Systems Come complete with a Support Superstructure, Access Platforms (Designed around Customers’ Specific Needs), and an appropriately sized Centrifugal Fan.

For Systems Requiring a more Efficient Collector, we can include an appropriately sized Baghouse by working with our Industry Partners.

Relying on our years of experience in the industry, we can recommend the best system to suit your filtration needs.

BINS, TANKS, AND SILOS

As with any industry engaged in manufacturing at scale, there is always a need for Material Storage. Here at Baxley Companies, we fabricate Storage Bins of nearly any size and shape. Baxley Bins are designed with YOUR FUTURE in mind.

This begins with material choice. All of our bins are at least 3/16 Carbon Steel (lighter options are available for light-duty applications) and reinforced with Angle Iron. The Angle Iron Reinforcements also set the stage for our Modular design. This Modular Design allows the end user to increase the size of the bin if needed down the road. It also reduces freight costs for our customers as we can normally get the bin to your facility without permits.

Many of the bins built throughout Baxley’s more than 75 years in business are still in use today.

WASTE LOADOUT

Along With Dust Collection Systems, Baxley Companies also offers a solution to the accumulation of waste products that are captured by our dust collection systems. Our Waste Loadout Systems integrate seamlessly with both our Cyclones, or Third Party Baghouses. We can also retrofit your existing Dust Collection Systems to accommodate a Waste Loadout System.

These Systems include an Engineered Support Frame, Material Conveyor, and all necessary Spouting. As with our Cyclone Superstructure, a Catwalk or Service Platform can be included based upon customer needs. Most of our Waste Loadout Systems are completely outdoors. However, an enclosure can also be added around the system if needed.

Our Customers have been able to generate secondary revenue streams simply by implementing one of these systems,

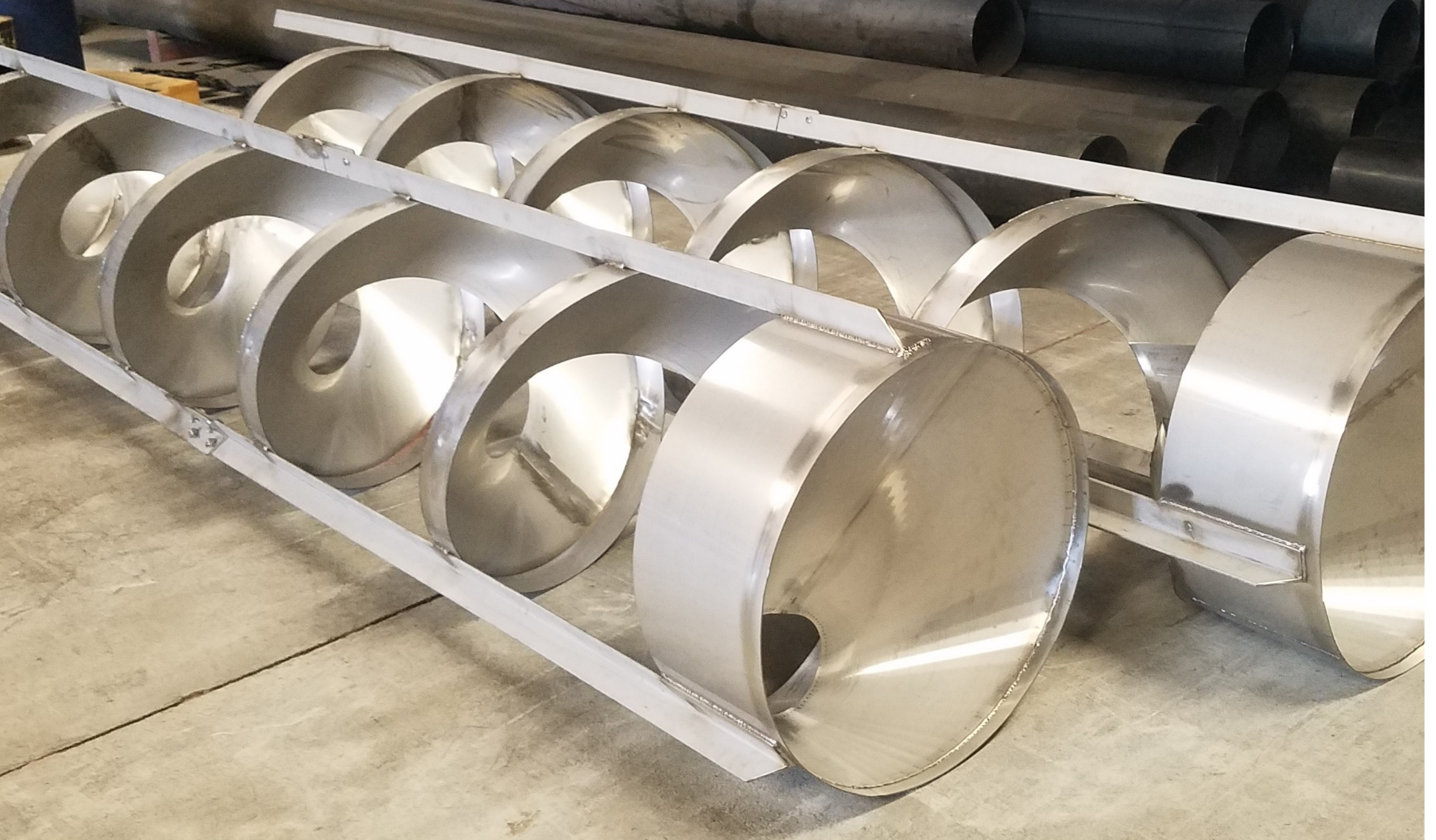

CUSTOM FABRICATION

Baxley Companies proudly offers a wide range of custom fabrication options. We are equipped to work with Carbon Steel, Stainless Steel, and Aluminum, as well as other alloys. We maintain a stocked materials warehouse that we pull from to build and sell to the public.

To work with this material, we have a full complement of equipment spread across two buildings consisting of (3) Press Brakes, (2) Shears, (2) Rollers, (1) Punch Press, (2) Band Saws, (2) Multi-Axis Mills, (2) CNC Lasers, (1) CNC Plasma.

We also have an in-house Paint Shop and Powder Coating Line. Applying our CONCEPT TO REALITY principle, along with our shop facilities, we are able to offer nearly limitless fabrication services.